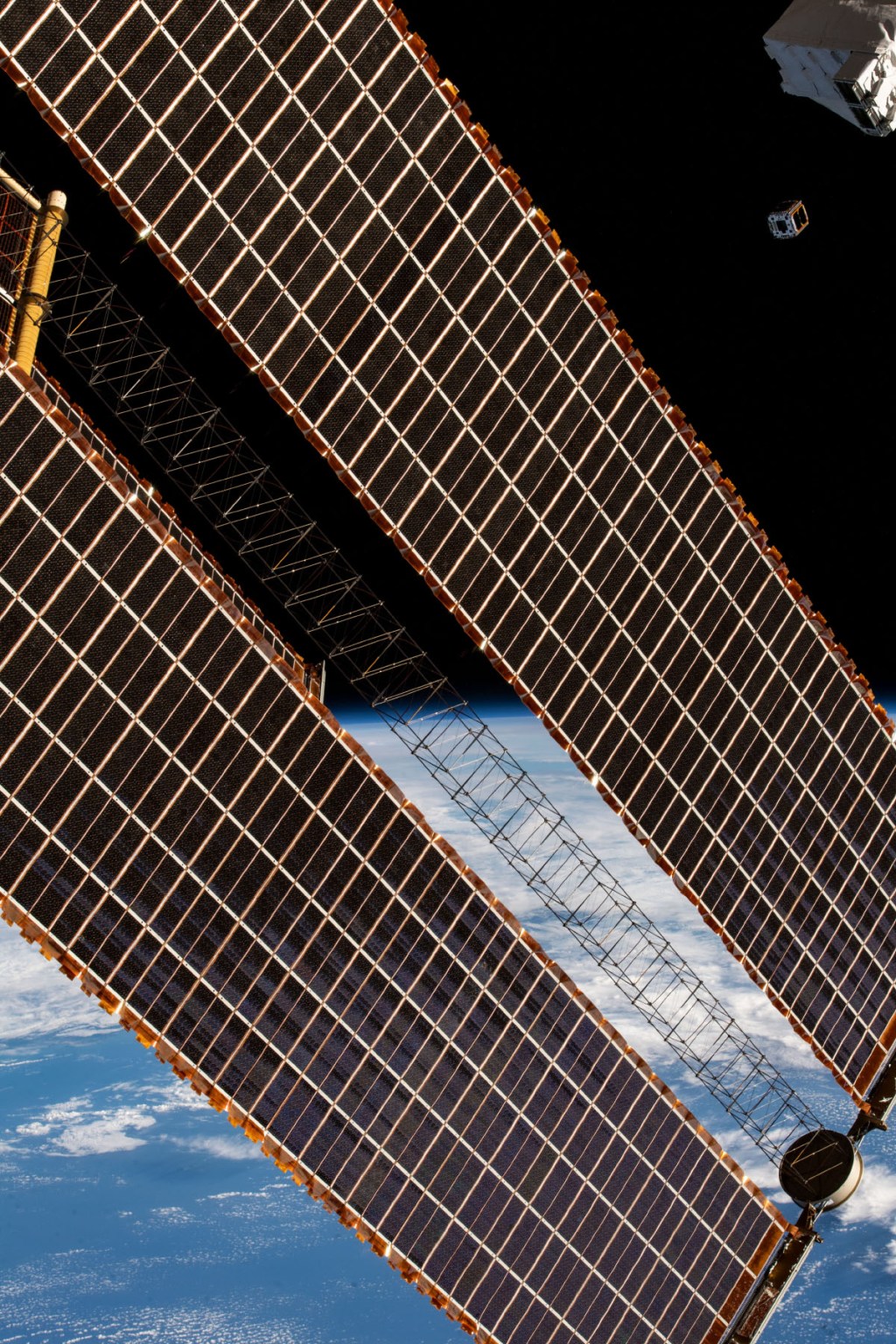

After four decades of microgravity research, NASA and the ISS National Lab have identified numerous applications that are within reach for NASA’s In Space Production Applications (InSPA) portfolio. Uniform crystals, semiconductors, specialized glass and optical fibers are just a few of the many advanced materials that can benefit from production in microgravity. Artificial retinas, drug delivery medical devices, as well as the production of pluripotent stem cells and bio inks are examples of how microgravity can stimulate the medical and bioscience industries. The most promising may be the production of small molecule crystalline proteins for pharmaceutical therapies. NASA’s InSPA objective is to enable sustainable, scalable, and profitable non-NASA demand for services and products manufactured in the microgravity environment of low-Earth orbit for use on Earth.

Applications of Special Interest

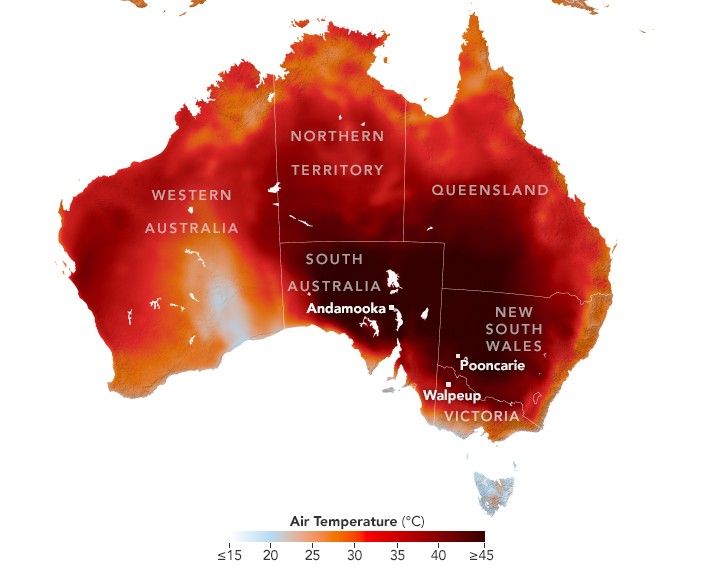

InSPA supports the goals of the White House’s “Cancer Moonshot” by seeking new applications that will accelerate the rate of progress against cancer. These projects are of special interest and may include manufacturing of compounds or therapeutics to address oncology applications on Earth.

InSPA also supports the CHIPS and Science Act of 2022, which provides the Department of Commerce with $50 billion for a suite of programs strengthen and revitalize the U.S. position in semiconductor research, development, and manufacturing. InSPA projects centered around semiconductor manufacturing are of special interest and can ensure United States leadership in semiconductor production. (Source: https://www.nist.gov/chips)

InSPA awards fall into two categories, Advanced Materials and Tissue Engineering and Biomanufacturing.

Advanced Materials

Advanced Materials use microgravity phenomena singly and in combination to produce a growing range of new products. For example:

- Removing sedimentation and buoyancy enables unique alloys and compositions.

- Surface tension processes can eliminate voids and ensure continuous contact between dissimilar materials.

- Lack of convection provides quiescent environments that can remove or minimize defects.

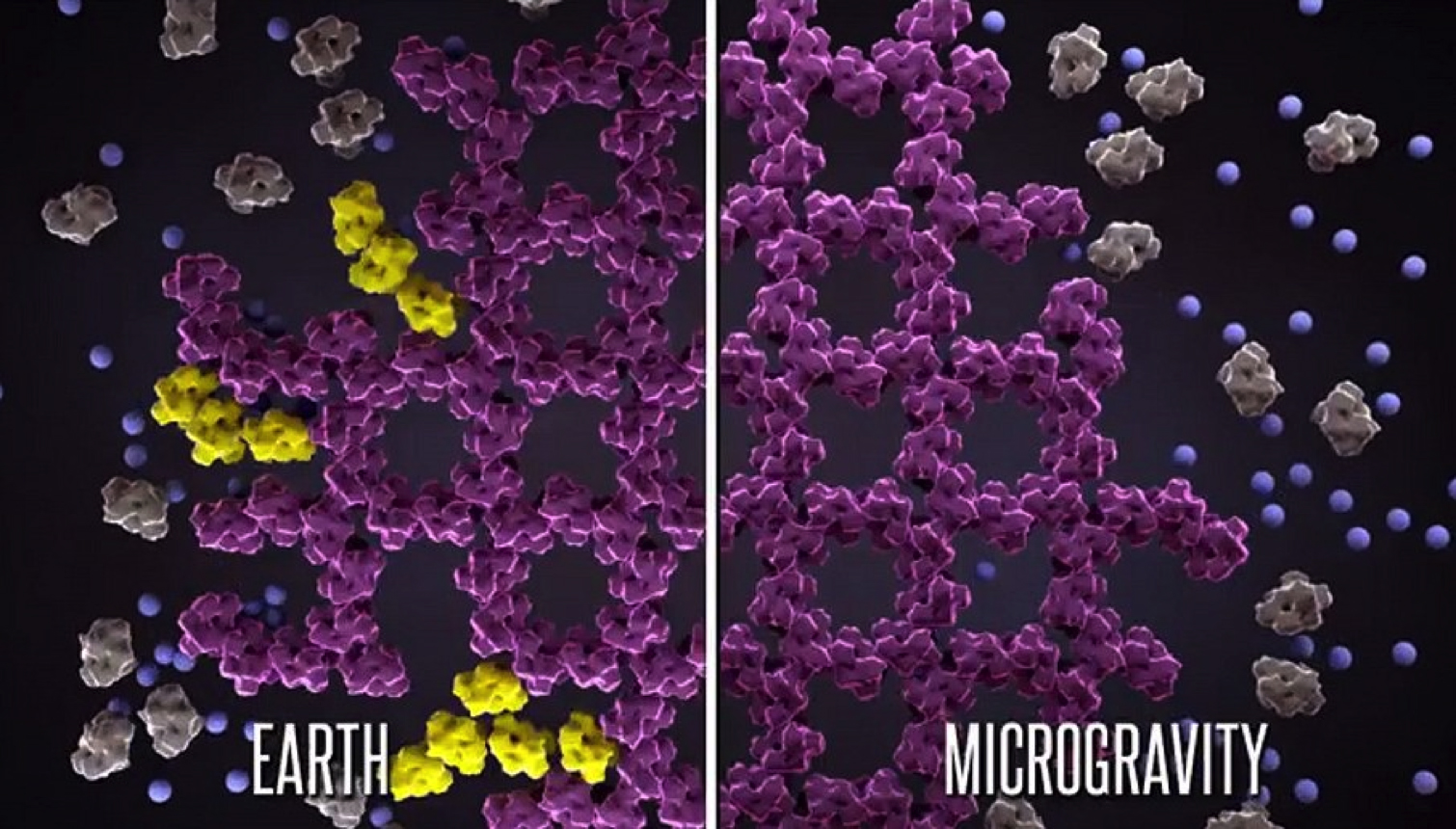

Crystal Production in microgravity has numerous applications in drug development, testing, and delivery, as well as semiconductors and inorganic frameworks. For example, crystals have the following properties in microgravity:

- They grow more slowly, enabling optical fiber manufacturing that suppresses crystallization defects.

- They grow in a more uniform manner that can better inform and enable better quality protein-based therapeutics.

- They grow larger and more perfect enabling exceptional quality industrial crystals and macromolecular structures.

techniques to be used in RTPCG-2.

Thin Layer Deposition in microgravity has applications in layering for medical devices, semiconductors, and ceramic coatings. For example:

- Absence of sedimentation and buoyancy allow surface tension effects to dominate, resulting in more uniform and atomically and molecularly precise layering for artificial retinas and other devices.

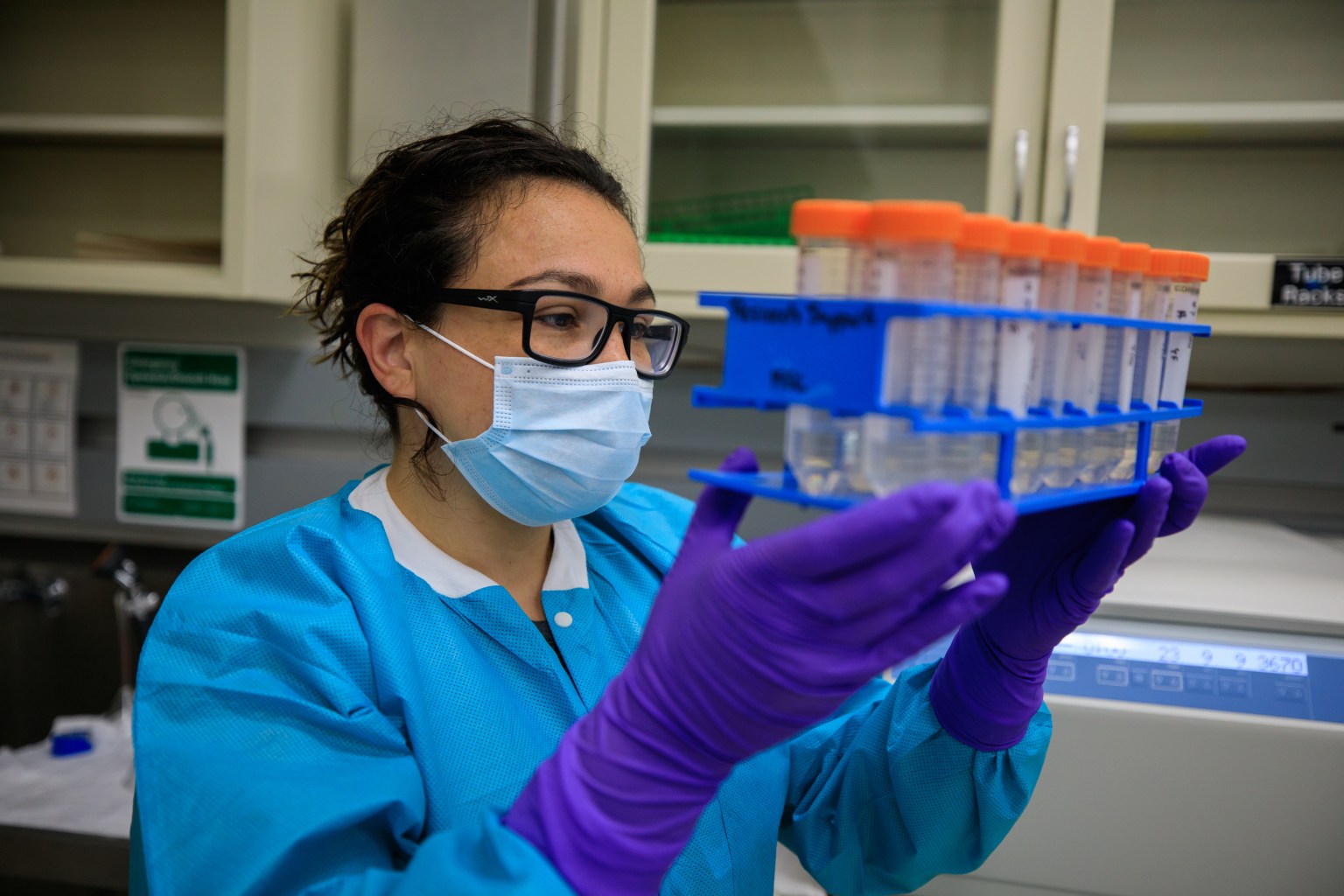

Tissue Engineering and Biomanufacturing

In microgravity, tissues can be formed in three dimensions without supporting architecture, and living matter adapts to microgravity through a variety of mechanisms that can be used to model cellular dysfunction, which occurs on Earth. For example:

- Gravity constrains tissue engineering on Earth by flattening and deforming 3D tissue constructs.

- Microgravity allows larger tissues to be constructed and used to inform medicine.

- Growing evidence indicates that the interaction of microgravity and living systems elicits responses similar to rapid aging on Earth that can be used to accelerate disease modeling and therapeutic development.

- Combined 3D tissue engineering with accelerated aging effects, informed by latest biotech and artificial intelligence and machine learning (AI/ML) offers new and rapidly growing knowledge, opportunities, and products for disease modeling, testing, and drug development.

Discover More Topics

from NASA https://ift.tt/drhJ3yi

No comments:

Post a Comment